Until recently, bundles (coils) were usually treated in salt, pickling, passivation and rinse immersion baths in discontinuous batches.

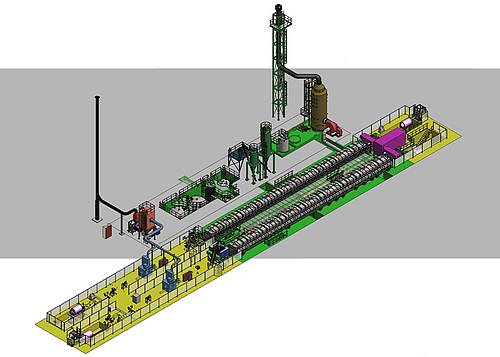

Now Steuler-Anlagenbau is bringing a high-efficiency processing method to the market. The special feature of this new system is that it can be used to treat individual wires of up to 5,000 meters long in a continuous spraying process. An upstream blasting unit removes up to 95% of metal oxides (rolling and mill scale), which reduces the acid and water consumption of the pickling line by up to 80%. That lowers operating costs for surface blasting considerably while improving surface quality at the same time – without producing any wastewater whatsoever. Along with iron, the metal oxides removed from the stainless steel wire surfaces by the blasting unit contain large amounts of chromium and nickel. They are reused as raw material in the stainless steel production process and recycled accordingly.

Instead of the usual mixed acid (HNO3/HF), this continuous pickling process can use hydrochloric acid (HCl) mixed with only a small quantity of hydrofluoric acid (HF) and nitric acid (HNO3). As a result, the process forms none of the nitrogen oxides which would necessarily be generated when using mixed acid. That, in turn, eliminates the high cost of having to install and operate a sophisticated waste gas purification unit.

Higher surface quality with lower investment costs, minimal acid and water consumption, and reduced operating costs – a wastewater-free turnkey solution that pays for itself and protects the environment at the same time.

The first units will go into operation soon: Steuler-Bobby Shanghai Equipment Engineering Ltd, a joint venture of Bobby (Shanghai) Ltd. and Steuler Anlagenbau, has already received an order from Wuxi Xingcheng of Wuxi, China for two such parallel roll pickling units. The scope of the order includes the complete engineering, fabrication, delivery and installation supervision up through the commissioning, which will be completed in 2016.